Cyant: What words of advice do you have for parents, and young Cyantists, who are inspired by your work and might one day want to work at the intersection of 3D printing and stop motion animation / storytelling? Are there skills they need to acquire? How can they cultivate their creativity?

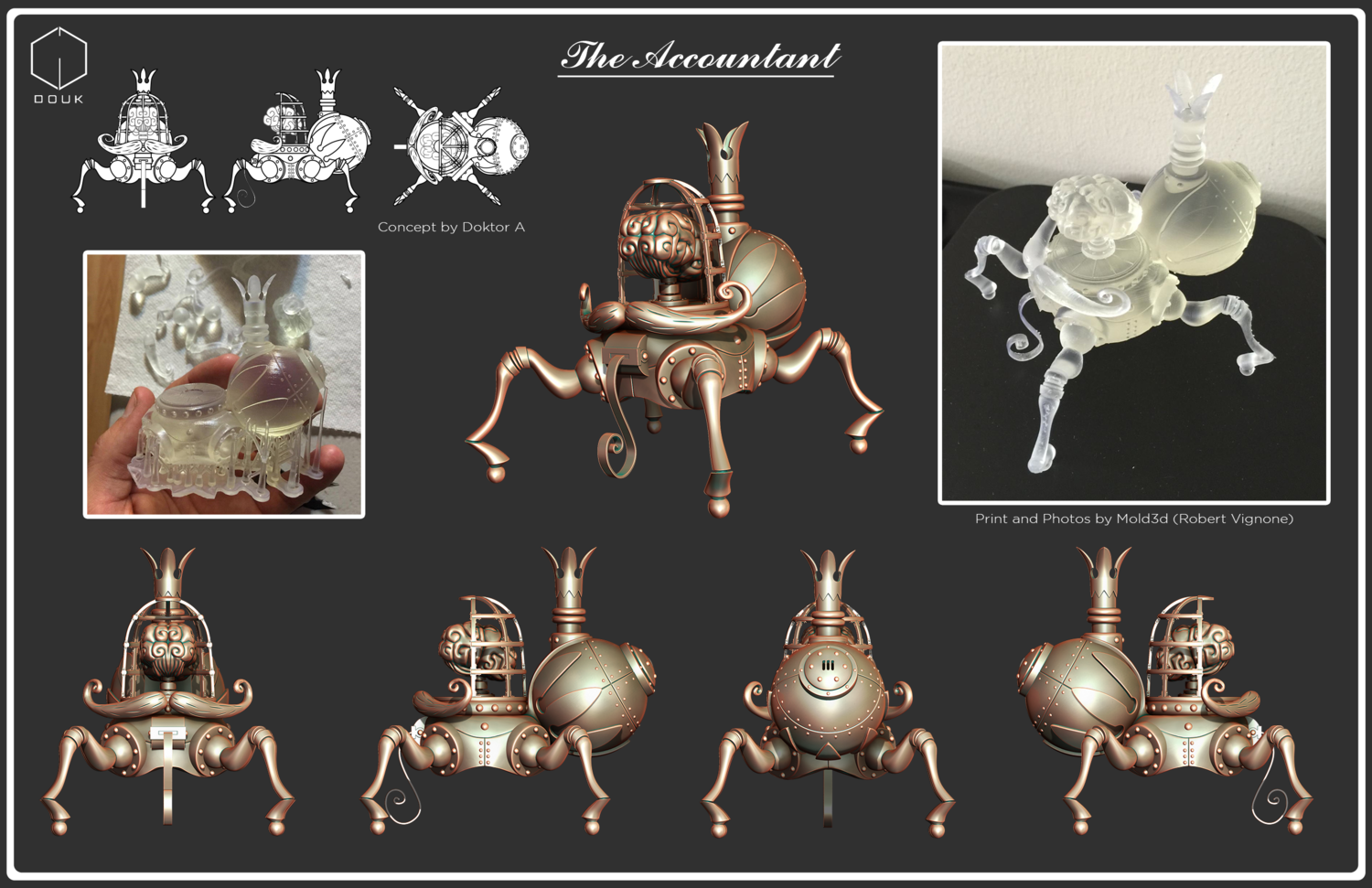

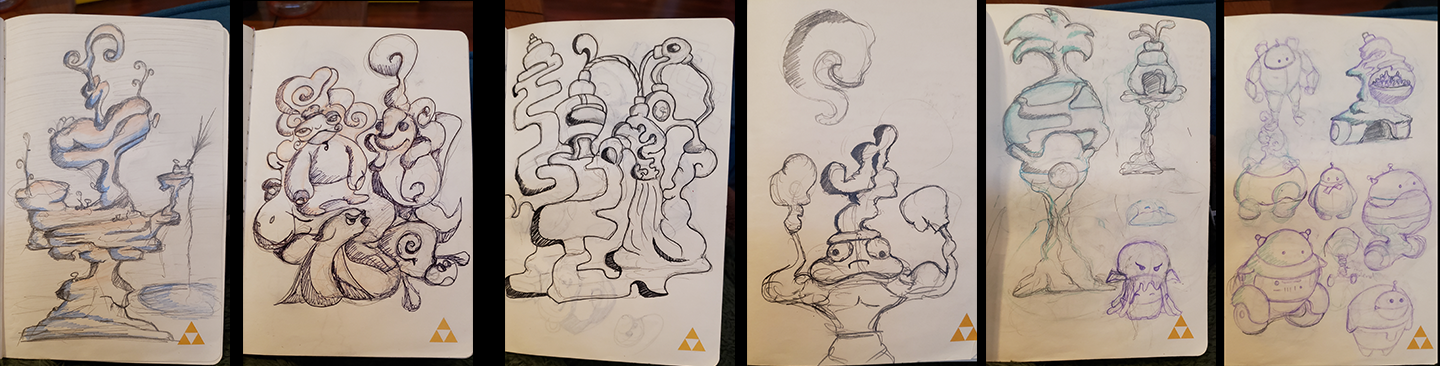

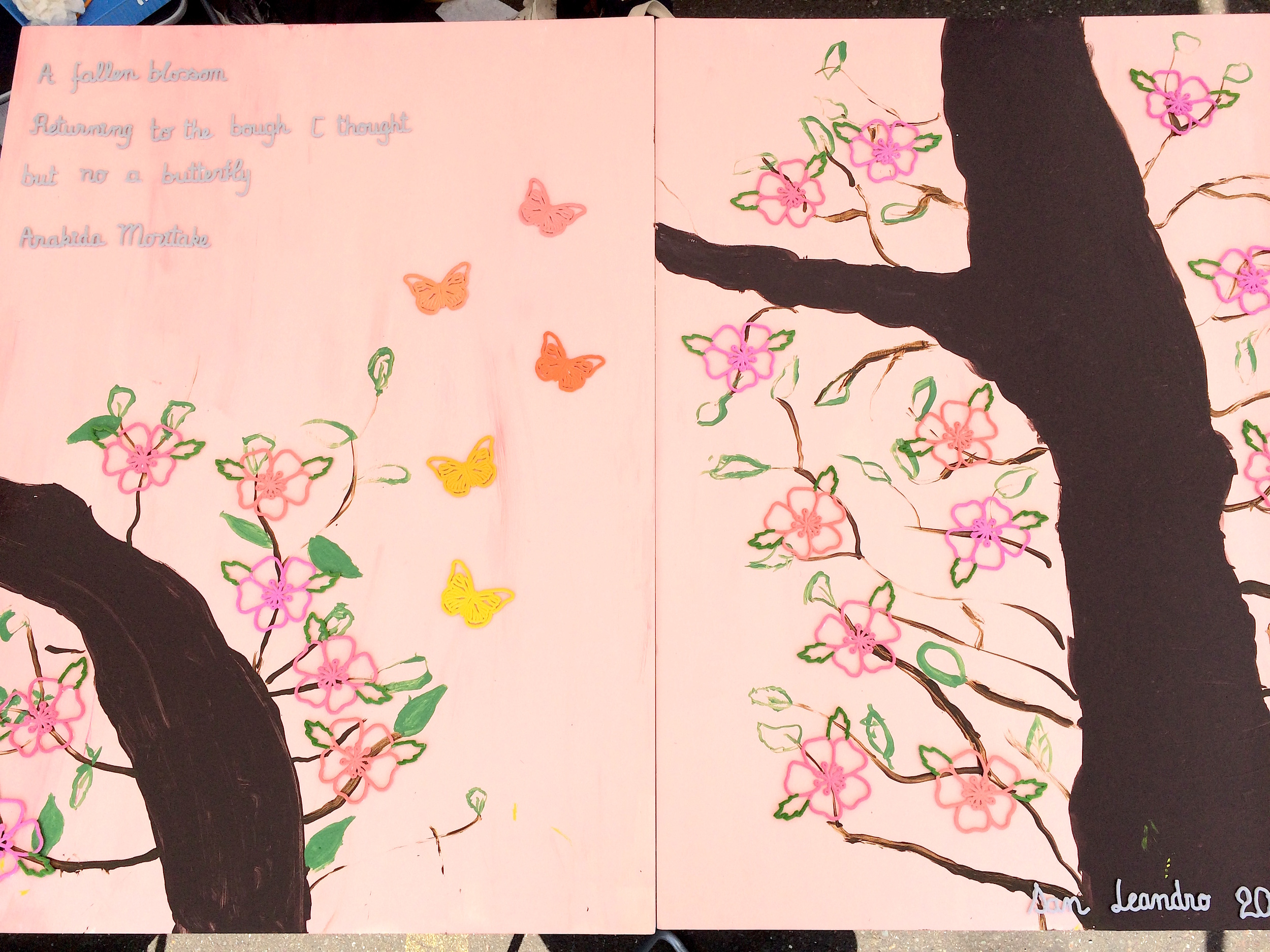

Brian: I can speak as someone who from an early age on, was drawn to the arts. Creativity can manifest itself in many different ways and you can find the connection really unexpectedly. Being able to encourage kids to be creative and artistic and allowing them to explore fields that may not seem like opening a career, is hard to do, but I think it’s necessary. Looking back at my journey, if I had not had the support from my family I may have had to choose another career. Arts and creativity are so important in our culture and our communities, and it is important for parents to find ways through which kids can feel supported in those fields. And as kids grow as students, there may be zigzags, and exposure to different people and different techniques, but it is part of the journey and learning who you need to be. The more tools they will have under their tool belts, the more they will be able to solve problems. And twenty years ago, the drive to find that art-meets-tech connection was not obvious: you were either art or tech. But there was never this idea that they could come together. Thanks to recent technology changes, such as smart phones, app development, building things really quickly in software or with 3D printing, the art-meets-tech connection has been brought back to the forefront. And we benefit from that everyday, that is a perfect blend of artists, technicians and computer geniuses that come together to solve a common problem.

Again we are grateful to Brian McLean for this Q&A, and Laika Publicist, Maggie Begley, for permission to use the images shown in this post. We leave you with a featurette that recounts the crafting of Kubo's magical journey, under the vision of Travis Knight, Laika's CEO.